A student uses a welding bay at Findon Technical College, a new high school in Adelaide where many teens are hoping to help build Australia’s AUKUS nuclear-propelled submarines. (Michael E. Miller/The Washington Post)

ADELAIDE, Australia — Ollie Filipponi always thought he’d be an electrician. But then the 16-year-old started at Findon Technical College, a new high school where the curriculum is partly designed by a defense contractor and the welding bays are modeled on those at the local naval shipyard.

Now the curly haired teen dreams of building nuclear-powered submarines. “That’s way cooler than wiring houses,” he said.

Ollie is one of the early beneficiaries of AUKUS, the trilateral security pact in which the United States and the United Kingdom are helping Australia build nuclear-propelled submarines to counter China’s growing military assertiveness in the region. Australia has committed to spend as much as $250 billion over three decades, first to acquire used submarines, then to build its own.

Although submarine construction won’t start for at least five years, Australia has already begun assembling an AUKUS workforce.

It is concentrated here in South Australia, where a new submarine shipyard is underway. To build these advanced vessels, this state of fewer than 2 million people will need thousands of shipbuilders and hundreds of engineers, according to federal and state officials and representatives of the defense industry.

The state government is boosting STEM — science, technology, engineering and mathematics — education in its elementary schools, including lessons designed by defense contractors.

Findon is the first of five new technical colleges built by the state to train teens for AUKUS-related careers. A local university is teaching nuclear engineering with U.S. assistance. And the federal government will soon fund 800 new places for university students to study STEM in South Australia, plus 3,200 more nationwide.

“We are moving at warp speed,” South Australia Premier Peter Malinauskas said in an interview.

The reelection of Donald Trump has injected some uncertainty into the future of AUKUS, however. While Canberra doesn’t expect Trump to scrap the plan, some analysts think Trump could seek to amend or renegotiate it. Australian opponents of AUKUS are meanwhile seeking to capitalize on the uncertainty and upend the deal.

But what that debate often overlooks — partly because the first subs won’t be completed until about 2040 — is that AUKUS is already very much underway in Australia.

“This is the biggest industrial endeavor that’s happened in Australian history,” Defense Minister Richard Marles said in an interview. “You can look at these time frames and say, ‘That’s a long way in the future.’ But, in fact, it’s not. Every day matters.”

About 60 members of the Royal Australian Navy are training to work on nuclear-powered submarines in the United States or the United Kingdom, according to Australian defense officials, and nearly a dozen are already serving on U.S. or U.K. subs. One even piloted the USS Hawaii into Perth in 2024 for the first maintenance of its kind outside the United States or a U.S. base.

Scores of Australian shipbuilders are in Pearl Harbor training on American subs ahead of rotations of U.S. and U.K. boats to Western Australia starting in 2027. Australia is spending $5 billion on upgrading a naval base in Perth ahead of the visits.

Both efforts are to prepare Australia for when it buys the first of at least three U.S. Virginia-class submarines around 2032. That’s also around the time Australia will begin building the first of five nuclear-propelled submarines here in Adelaide.

“This is a huge horse that we’re getting on here,” Marles said. “We can’t just magic this.”

Ollie Filipponi, left, Isla Taylor and Matt Goldsworthy collaborate on a metal-working project at Findon Technical College. (Michael E. Miller/The Washington Post)

A construction and training boom — at a cost

Australia’s future nuclear submarine factory is currently little more than an empty field on the banks of the Port Adelaide River.

But this barren patch of the Osborne shipyard is where BAE Systems, a British defense contractor, will build the AUKUS-class sub with a local company, ASC.

The AUKUS sub is being designed by a U.K. team with Australians “embedded” in it, said Craig Lockhart, chief executive at BAE Systems Australia. The United States is also closely involved since the sub will use U.S. technology and weapons, and preliminary designs are more than 75 percent complete, he said.

A joint venture between the two companies will hire roughly 5,000 people over the next decade. The state and federal governments will begin building a skills academy at Osborne this year to train young sub-builders. And as the shipyard goes up, so, too, will schools, day care centers, housing and transportation links.

Something similar is happening in Western Australia, where Perth’s HMAS Stirling naval base is being prepared, to the tune of $5 billion in wharf upgrades and new facilities, for deployments of American nuclear-propelled submarines in 2027.

AUKUS will create 20,000 jobs in Australia, officials say. But at a cost of up to $250 billion, that works out to roughly $12 million per job, and some critics argue that the program doesn’t justify the price.

“It’s an incredibly inefficient way of creating jobs for people who, for the most part, are already employed,” said John Quiggin, a professor of economics at the University of Queensland.

Marles, the defense minister, countered that Osborne will have some of the world’s most advanced production lines, saying that “there’s no doubt that will flow into the wider economy.”

He wants to speed up South Australia’s pilot program to bring local companies into the U.S. nuclear submarine supply chain. The effort is being run by HII, one of two U.S. shipbuilders who make Virginia-class subs. If Australian companies can make some parts, it will speed up U.S. production and prepare Australia to maintain its Virginia-class vessels and, eventually, to make the AUKUS sub.

“What we’re trying to do is help ourselves and in the process establish sovereign Australian capability,” said Michael Lempke, who leads HII’s AUKUS efforts, adding that the company will soon launch a similar program in Western Australia.

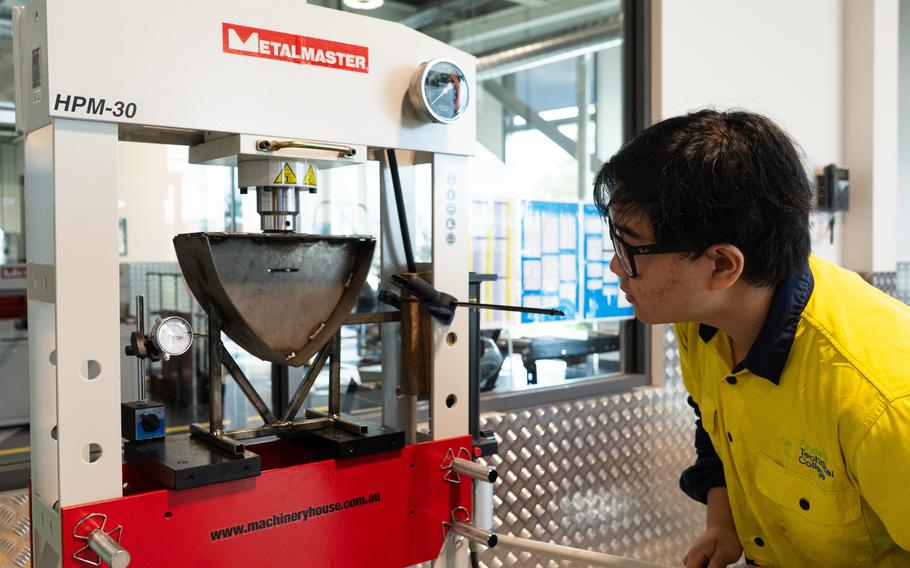

Justin Lai conducts a stress test on a ship cradle in a program at Findon Technical College partly designed by BAE Systems. (Michael E. Miller/The Washington Post)

AUKUS education starts in elementary school

Students as young as 9 recently gathered in a classroom in the small town of Moonta, two hours from Adelaide. Using tablets and a 3D modeling program supplied by BAE, they designed an underwater gadget.

The company soon will sponsor similar projects in 80 elementary schools across South Australia. The program is one of several new state initiatives designed not only to promote STEM but also to make students comfortable with the defense industry.

“There are people who are just starting primary school who we would hope to have a career in AUKUS,” said Lockhart, of BAE. “We need to be influencing the academic curriculum today, not only to build up the social license for what we’re trying to achieve but also to try to attract the very best students.”

The initiatives have been met with little protest in an industrial state still searching to replace its auto plants, the last of which shut in 2017.

At Findon, half the students in its advanced manufacturing and engineering pathway are hoping to work for BAE, said instructor Joel Phillips. The defense contractor helped design the curriculum and welding bays, he said. Findon’s workshop even has yellow safety lines on the floor just like at Osborne.

Isla Taylor commutes four hours every day after her previous school stopped teaching engineering. The 15-year-old was blown away by a field trip to BAE’s shipyard. “AUKUS is one of the main things we talk about here,” she said.

Some Findon students will head to local universities, which are also transforming for AUKUS.

Last year, Flinders University brought in professors from the University of Rhode Island to teach nuclear engineering to undergraduates. This year it will also offer graduate courses and paid apprenticeship degrees with BAE and ASC.

Michael Ly, 16, plans to study software engineering in university before joining BAE. He never thought of working in defense until coming to Findon, he said as he pulled up a ship cradle design on his laptop. Now he was hoping to focus on cybersecurity. “We’re going to need that when we’re building submarines,” he said.

As a student sparked a welding torch with an air-splitting crackle, Filipponi practiced on a digital welding machine. In six years, the steel hull of an AUKUS sub would start to take shape nearby. The teen wants to be part of the effort.

“That,” he said, “would be awesome.”