()

ABOARD USS HARRY S. TRUMAN (Tribune News Service) — If something breaks when a warship is out at sea, finding a replacement isn't as simple as running out to the hardware store.

So the Navy is turning to technology to enable sailors to produce custom parts aboard their ships using 3-D printers. The miniature fabrication labs have been placed on two ships: the aircraft carrier Truman and the amphibious assault ship USS Kearsarge. Both Norfolk-based ships are deployed to the Middle East in the fight against the Islamic State.

"The whole goal is really to make us more self-sufficient as we deploy," Cmdr. Brady Drennan said while viewing the Truman's small printing facility. "Because when we leave the pier, we basically leave all the supplies, all the equipment, all the tools there."

Within their first weeks of deploying in November, sailors already had created and "printed out" custom dust caps and a wrench. A sailor in the "fab lab" designed his own solution after he and others grew frustrated that an oil cup on a machine was too small for a funnel.

"It required at least two people to get all the oil in the cup, so I figured we have this technology here, why not try something that would make this task easier," Petty Officer 2nd Class Raymond Lee said. "I came up with an extension that narrows the nozzle, cuts the manpower in half, ensures there's no spilled oil all over the deck."

Officials aboard the ship say ideas for using the printer are pouring in from sailors.

"I think the possibilities are endless," Lee said.

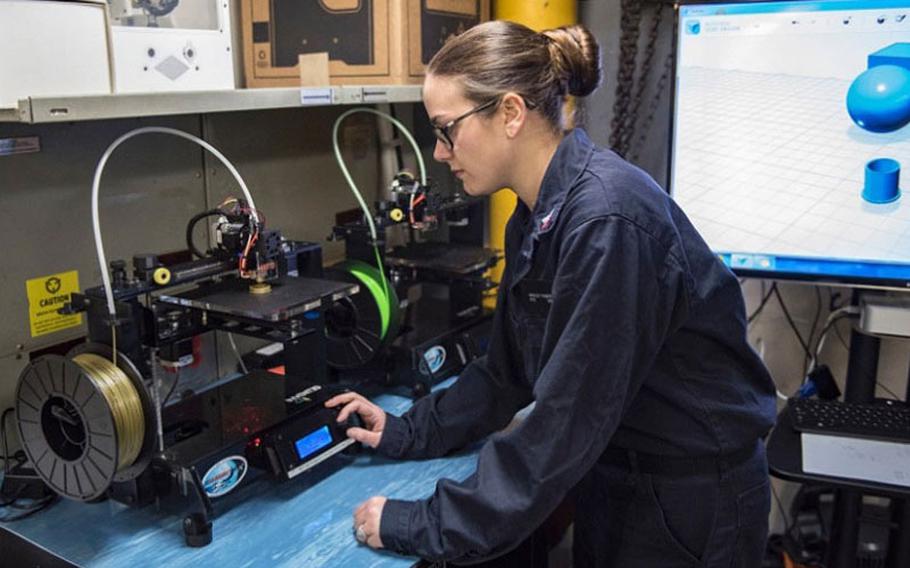

The 'fab lab' consists of two 3-D printers, a desktop computer and a large flat-screen monitor with a wireless keyboard and mouse. The printers are similar in size and shape to a traditional desktop printer.

The Truman's sailors can design just about any shape they need and print out a plastic version of it. If something bulkier needs to be manufactured, they still can design it to their specifications and have it printed ashore and delivered.

The sailors largely are testing out the design software and printer's abilities by trial and error. The fab lab was installed aboard the Truman by the Mid-Atlantic Regional Maintenance Center only three days before the ship left.

"They contacted us about basically an experimental opportunity to do this mini fabrication ... kind of designing and testing and so forth," said Cmdr. Al Palmer, the ship's maintenance officer.

Lt. (j.g.) Casey Staidl said the 3-D printers are ideal because working and living aboard a ship requires unique solutions.

For example, Staidl said an ordnance sailor had a problem with not having enough room in a workspace because some desks were welded to the floor. The sailor wanted to hang a monitor from a specific angle, Staidl said.

"Our guys are actually drawing up the actual specs and they're going to create them an actual kind of floating stand so they can get the monitors up and they can get them out of the way so they have more room to do their job," he said.

"It's just one of those kind of unique things that aren't in any kind of office – it's ship life, so it's one of those practical uses that we can use to help their lives."

©2015 The Virginian-Pilot (Norfolk, Va.)Visit The Virginian-Pilot (Norfolk, Va.) at pilotonline.comDistributed by Tribune Content Agency, LLC.